Robotic Quality Inspection System

Product Details:

- Product Type Other

- Power Source Electricity

- Operating Type Automatic

- Warranty 1 Year

- Usage & Applications Pharma industry

- Click to View more

X

Robotic Quality Inspection System Price And Quantity

- 1 Unit

Robotic Quality Inspection System Product Specifications

- Automatic

- Other

- Pharma industry

- Electricity

- 1 Year

Robotic Quality Inspection System Trade Information

- 10 Days

Product Description

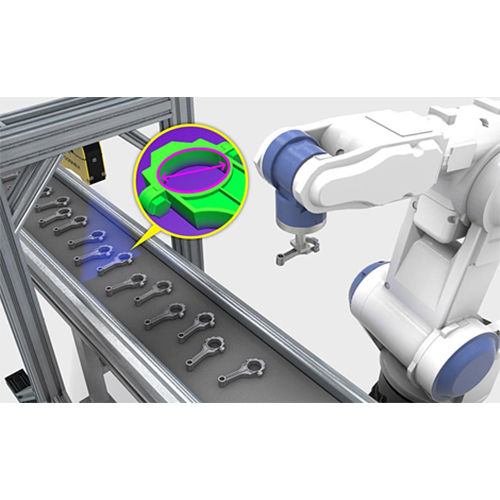

iR-RoboQV is a Robotic Quality and Vision checking system. Which is a combination of robot and vision system for quality check of different shapes, size and multi places checking applications.

We can have human limitation to check with on job and different aangles which can be customized with Robo + Vision combination. iRobolution is having unique design idea based on application to give customize solution and quality reports.

Why iR-RoboQV:

We can have human limitation to check with on job and different aangles which can be customized with Robo + Vision combination. iRobolution is having unique design idea based on application to give customize solution and quality reports.

Why iR-RoboQV:

- Unique design position

- Specific Vision software design for the solution

- Methods of Quality Checks and Reporting

- Small footprint

- Customize design

- Advance control system to give you all alarms and warring massages.

- Robot selection for operation

- Griping system with iGripp Technology Design

- Conveying system

- Vision and Lights combination

- Control system with Industry 4.0 ready

Application:

- Automobile, Casting

- Pharma industry

- Packaging industry

Innovative Automatic Inspection for Pharma

Leveraging cutting-edge robotics and automation, this quality inspection system delivers fast, precise assessments of pharmaceutical products. By using electricity as its power source, it operates continuously with minimal downtime, ensuring that every item meets stringent quality standards. The systems design facilitates effortless installation, making it an ideal choice for manufacturers seeking to upgrade their quality assurance capabilities.

Reliable and Hassle-Free Maintenance

This inspection system offers a 1-year warranty, underlining its durability and ease of maintenance. Its automated functions reduce manual interventions, allowing staff to focus on other value-adding tasks. Routine check-ups and technical support are available across India, ensuring the system remains in peak working condition throughout its service life.

FAQs of Robotic Quality Inspection System:

Q: How does the Robotic Quality Inspection System improve quality control in the pharma industry?

A: By utilizing advanced sensors and automation, the system streamlines inspection processes, detects defects early, and minimizes human error, safeguarding product quality and compliance with industry regulations.Q: What steps are involved in the inspection process carried out by this system?

A: The inspection process begins as products enter the systems designated area, where cameras and sensors automatically scan for irregularities or defects. Any anomaly is flagged, enabling immediate corrective action.Q: When should a pharmaceutical manufacturer consider integrating this automated system?

A: Manufacturers aiming to enhance their quality assurance, boost productivity, or meet escalating regulatory demands should consider integrating this solution as soon as quality management becomes critical.Q: Where is this Robotic Quality Inspection System available and who are its main users?

A: The system is available throughout India, serving exporters, manufacturers, and suppliers in the pharmaceutical sector looking to ensure consistent product quality and compliance.Q: What benefits does the system offer over manual inspection methods?

A: Unlike manual inspections, this automated system increases throughput, provides consistent accuracy, reduces labor costs, and decreases the risk of defective products reaching the market.Q: How is the system powered and maintained?

A: The system operates on electricity, providing reliable power for uninterrupted inspections. Regular maintenance is straightforward, with technical support and a 1-year warranty ensuring operational stability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese