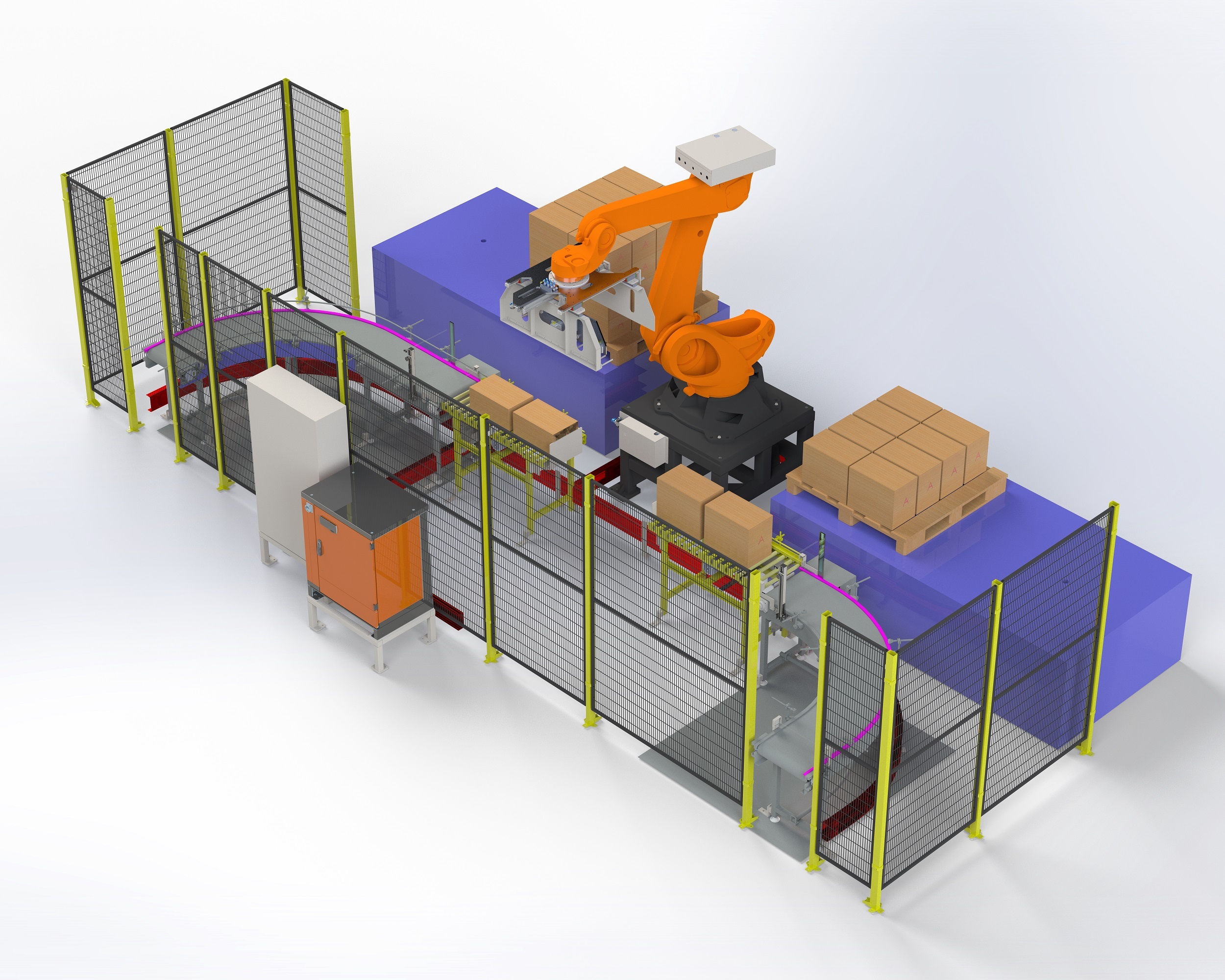

Robotic Palletizer

Product Details:

- Noise Level <75 dB db

- Features Energy-efficient, low maintenance, safety guarded

- Power Supply Three-phase AC

- Application Palletizing cartons, bags, and boxes in packaging lines

- Usage Automated palletizing in manufacturing and logistic sectors

- Type Robotic Palletizer

- Material Stainless steel

- Click to View more

Robotic Palletizer Price And Quantity

- 1 Unit

- 4500000 INR/Unit

Robotic Palletizer Product Specifications

- 380 Volt (v)

- 180 Kg/hr

- Automated palletizing in manufacturing and logistic sectors

- Automatic

- 2800*2200*2300 Millimeter (mm)

- 5.5 Watt (w)

- Yellow

- Stainless steel

- Robotic

- Robotic Palletizer

- Palletizing cartons, bags, and boxes in packaging lines

- Three-phase AC

- Energy-efficient, low maintenance, safety guarded

- 950 Kilograms (kg)

- Yes

- PLC Control

- Other

- <75 dB db

- Electric

Robotic Palletizer Trade Information

- 10-15 Days

Product Description

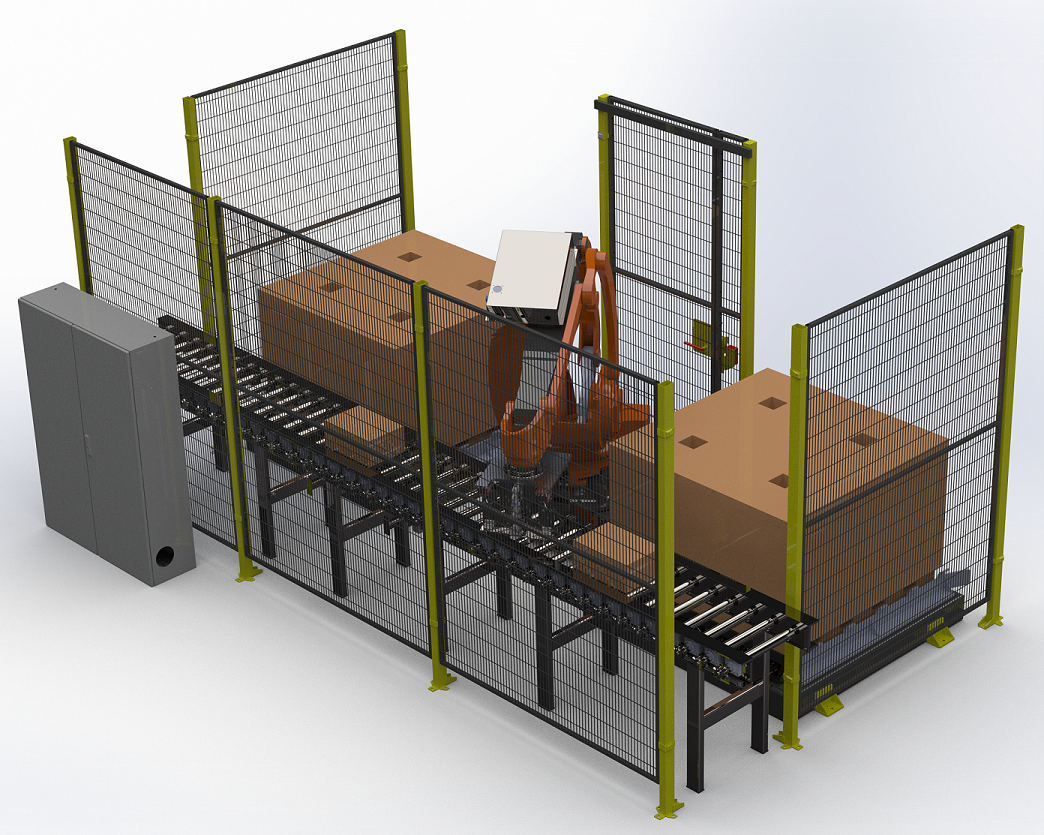

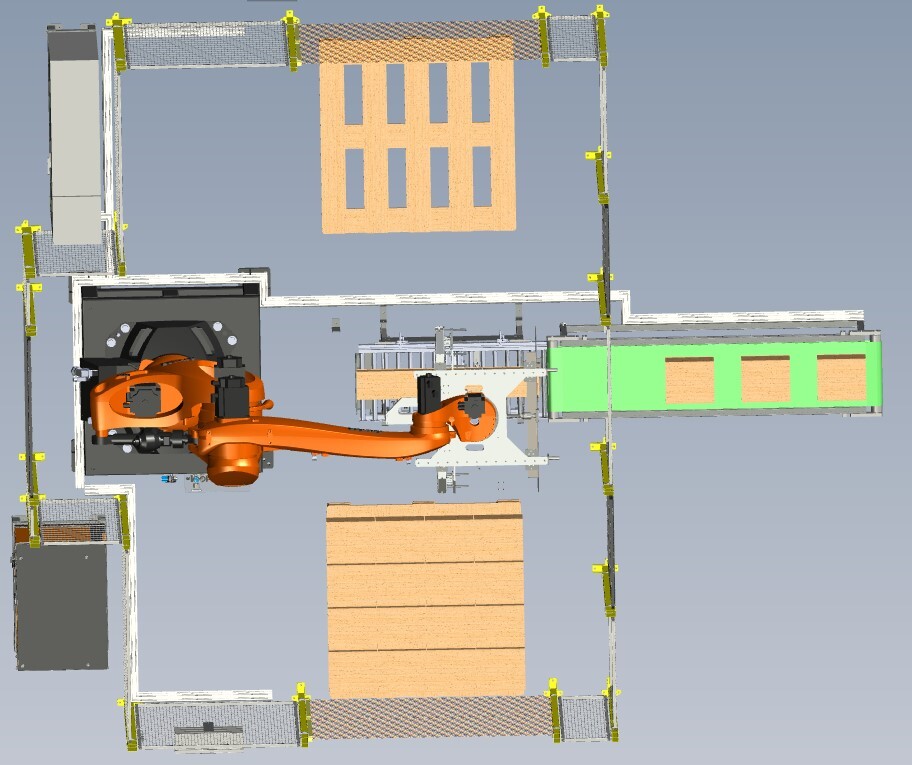

Robotic palletizer (iR-iNovatRPa) is a system that is capable of handling the most vital fragment of end of the line. iR-iNovatRPa is a fully integrated robotic system that has a flexible design, robust build, and easy installation. This well-designed technology can handle multiple lines in the manufacturing/production area. Robot palletizer application handles water 20L jar, any size of drum up to 50KG, carton palletiser, Bottles shrink-wraps, Crates, Bags to palletize as per matrix formation.

A fully automatic system that can run without an operator input apart from charging a stack of pallets and unloading finished pallets off after the palletizing operation. iNovat products are ready to integrate with ASRS, AGV/AMR solutions and any Digital platform to provide data for reporting and analysis.

- Palletisers for cases and boxes (iR-MCE-10)

- 810 beats per minute Machine for vertical case erector

- (iR-MCE-15) between 12 and 15 bpm Machine for vertical case erector

- Case Packer Robot

- iR-GCP, or gantry case packer

- Robotic vision system

- Unpack bottle iR dpa

- Drum iR dPaBox

Why iR-iNovatRpa:

- Reduces severe injury & fatigue to workers. Focus on human safety.

- Increasing production throughput, productivity, and efficiency.

- Very Low Maintenance compare to traditional heavy gantry systems.

- Flexible and unit gripper design- iGrip & system design

- Highly repeatability and reliability.

- Teachable for New SKU, New matrix formation.

- Touch panel-based user-friendly operating system for operation, error reporting, diagnostics etc.

- Remote support module for worldwide support to connect

- Industry 4.0 enabled, IIOT enabled

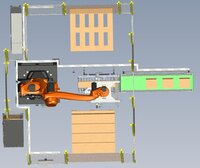

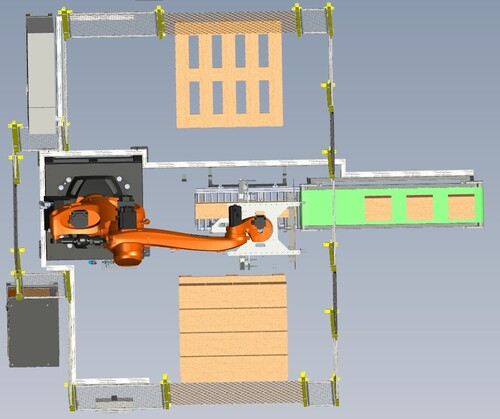

iR-iNovatRpa includes:

- Customized well know Robot brands for palletizing

- Custom-built robots gripper (Innovative gripper designed to handle various sizes of products/matrix) thanks to iGrip Technology Design

- Automatic pallet feeding system.

- Pallet feeding conveyors

- An infeed conveyor integrated with the output of your production process.

- Touch screen control system with flexible integration software design.

- Guarding and doors with interlocks and safety as required with CE/UL compliance.

- Ethernet connectivity for remote support

- Application Industry:

- Automation

- FMCG

- Homecare

- Personal care

- Soap industry

- SanitaryCare

- Pharmaceuticals

- Medicine

- Pathology

- Adhesives

- Paints And Coatings

- VehicleCare

- AgroChemical

- SpecialtyChemicals

-

Adaptable Performance in Challenging Environments

Engineered with stainless steel and sealed electrical components, this robotic palletizer thrives in dusty and humid conditions common in industrial settings. Its robust design and floor-mount installation ensure stable, long-term operation, even in demanding environments.

Precision, Speed, and Safety in One Package

With a maximum load capacity of 130 kg and a cycle rate of 180 cycles per hour, this system delivers high-speed, precise palletizing. Built-in safety curtains and an emergency stop offer comprehensive safety, keeping operators protected while maximizing productivity.

Simplified Operation and Minimal Maintenance

Programming tasks are streamlined with a user-friendly HMI touch screen and a reliable PLC control system. The energy-efficient electric drive reduces maintenance and operational costs, ensuring low noise levels and sustained performance over a 60,000-hour service life.

FAQs of Robotic Palletizer:

Q: How does the robotic palletizer ensure safety during operation?

A: The palletizer is equipped with integrated safety curtains to restrict access during operation, and an emergency stop function for immediate shutdown. These features help protect operators and maintain a safe working environment.Q: What types of items can this palletizer handle, and how customizable is the end effector?

A: This system can palletize cartons, bags, and boxes, making it ideal for various packaging lines. Its customizable gripper can be tailored to match the specific shape and size of your products, ensuring optimal handling and placement.Q: When is this robotic palletizer best utilized in the production process?

A: The palletizer is typically used at the end of the packaging line, automating the stacking of packed products onto pallets for shipment or storage, which improves throughput and reduces manual labor requirements.Q: What installation requirements should be considered for this palletizer?

A: It requires a stable, floor-mounted setup with three-phase AC power (380V), and dimensions of 2800x2200x2300 mm. Ensure sufficient space and access for loading and routine maintenance.Q: How user-friendly is the programming and operation interface?

A: The system features an intuitive HMI touch screen, which simplifies programming and operation. Even operators without extensive technical backgrounds can configure and monitor palletizing tasks efficiently.Q: Where can this robotic palletizer be effectively used?

A: It is well-suited for manufacturing plants, logistics centers, and warehouses where automated, efficient, and precise palletizing of various products is required, especially in environments where dust or humidity is present.Q: What benefits does the robotic palletizer offer compared to manual palletizing?

A: Utilizing this system increases productivity, ensures consistent stack quality, lowers labor costs, and enhances workplace safety. Its energy-efficient, low-maintenance design translates to reduced operational expenses over its long service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese